Coolers

Coolers

RLS 10 à 15

Our RLS range of cooling systems are designed to control the temperature of high-tech industrial processes in industries as diverse as watchmaking, automotive, aerospace, pharmaceutical laboratories, plastics and chemicals.

Options and Accessories :

- HP control with pressure sensor

- Flow and level controllers

- Harting plugs, ...

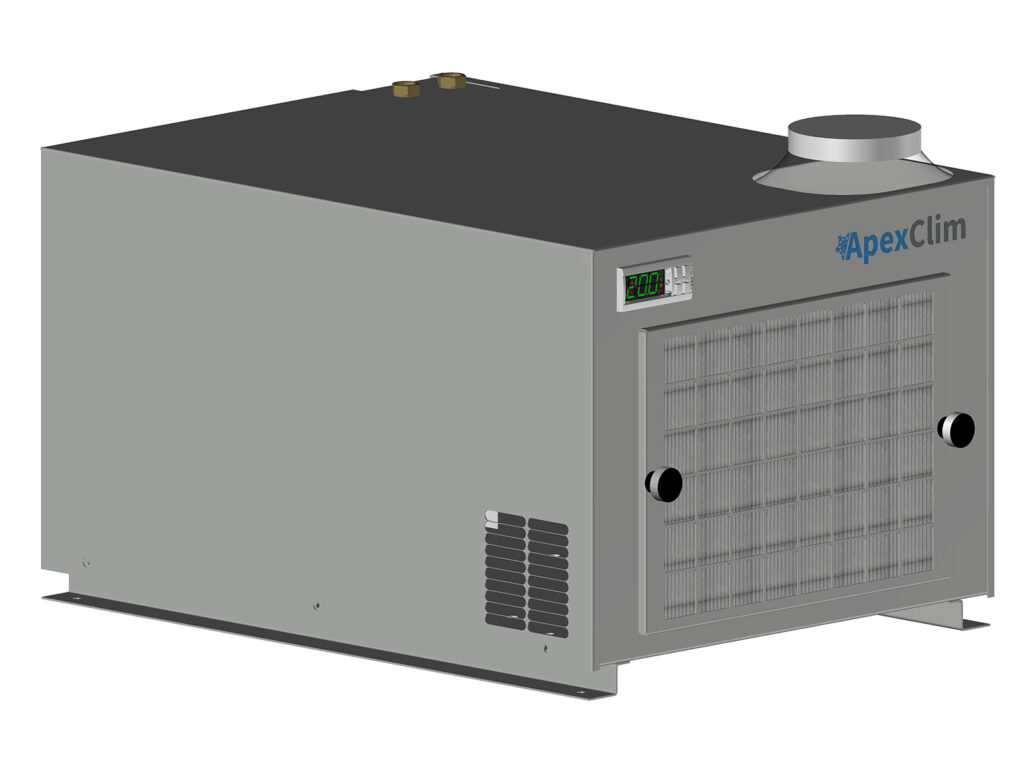

RLS 20 à 35

Our condensers have been specially designed and developed to operate without filtration of the ambient air.

Their surfaces and mounting are important factors in the performance of our machines.

Area of Activity

RLB 8U or 16U Single-phase

Spindle liquid

Our RLBs are self-contained units with optimised dimensions for cooling industrial processes.

Specifications

- Hydraulic power stations

- Scanning electron microscopes

- Plate heat exchangers (computer rack)

RLB 8U or 16U Three-phase

Spindle liquid

A wide range of options are available for securing your applications.

Specifications

- Flow regulator

- Level detector

- Two-speed condenser fan

RLC 50 à 120

Cutting fluid

The RLC range of coolers has direct expansion on the liquid thanks to a copper or stainless steel coil-type exchanger, which is inserted directly into the liquid tank to be cooled (the liquid must be moving).

Available options

- Fault reporting, time delay, ...

- Remote start-up

- Two-speed fan-condensers

- Heating resistor

RLC 150 à 502

Cutting fluid

Optional equipment

- Heating resistor with a power rating of 4 to 15 kW.

- Hot and cold control (resistor installed on the tank and autonomous RLC control).